1 / 4

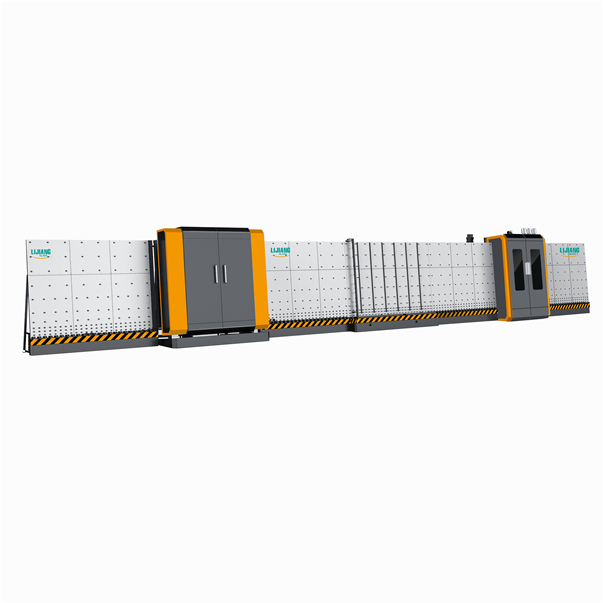

Linha de processamento de vidro isolante vertical

$90000.00

≥60000 Set/Sets

| Brand Name : | Lijiang |

|---|---|

| Applicable industry : | Hotels,Restaurant,Other,Advertising Company,Home Use,Garment Shops,Building Material Shops,Retail,Food Shop,Printing Shops,Manufacturing Plant,Construction Works,Machinery Repair Shops,Energy &Amp; Mining,Food &Amp; Beverage Factory,Food &Amp; Beverage Shops,Farms |

Jinan, Shandong, China

- Fabricante

- Serviço OEM

- Certificação da plataforma

- Expo online

Descrição do produto

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Automatic Insulating Glass Production Line LJBZ2535 We can provide online remote monitoring, installation and commissioning services during the outbreak

Main Features: • Adopt SIEMENS control system, keep stable performance • PLC control system, touch screen interface • Automatically adjust the depth of glue with digital display • Using servo to control system, modular function, superposition function • Applicable to produce stepped IG, triple IG and shaped IG • Two pieces of IGU can be made and filled with argon gas in one time (Optional) • Min & Max glass sizes can be optional

Technical data

Parâmetros elétricos

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Advantage of Press machine: • Two pieces of IGU could be pressed and filled gas in once time, each IGU could fill argon gas over 90%. • Can be better prevented the pressing part to be out of shape by pressing two pieces of IGU in once time. • High-speed IG processing line • Solving the problem of waiting for working on the sealing robot. Improve work efficiency highly. • Installing two spacer frames for two IGU by one workman. • Automatically measuring glass size and labeling (labeling can be allowed before pressing and after pressing) with ERP system. • From transfer part to pressing part, each part is divided. • Suitable for mass production in a factory, Ultra-fast speed.

|

Outro equipamento de vidro isolante da nossa empresa:

1. Linha de produção de vidro insultante

2. Máquina de flexão de spacer

3. Máquina de enchimento do DesicCant

4. Máquina de extrusor de butil

5. Robô de vedação de vidro 5.

6. Máquina de lavar de copos

Kation-Tech founded in 2009, specializes in R&D, production and sales of Insulating glass machinery and related auxiliary equipment for the glass deep processing industry and the door and window construction industry. Has the professional processing basis of i

Jinan, Shandong, China

- Fabricante

- Serviço OEM

- Certificação da plataforma

- Expo online

Envie sua pergunta a este fornecedor