1 / 3

1x1000 mm2 38/66 (72,5) CA CABO DE FORÇA kV CU / XLPE / LS / CWS / PEAD

| Model No. : | YJQS03 |

|---|---|

| Brand Name : | HUAYUAN YONGTONG |

| Type : | Insulated |

Beijing, Beijing, China

- Distribuidoratacadista

- Fabricante

- Serviço OEM

- Certificação da plataforma

- Vídeo

Descrição do produto

1. GERAL

Esta especificação listada cobre a estrutura, desempenho, teste e informações de embalagem do cabo de energia EHV como fabricado por Pequim Huayuan Gaoke Cable Co., Ltd.

As questões não mencionadas nesta especificação técnica devem ser negociadas pelo comprador e pelo fornecedor. Este documento confirma o acordo entre as duas partes como acordo técnico do contrato, salvo disposição em contrário nos anexos oficiais por escrito.

2. NORMAS APLICÁVEIS

O cabo oferecido deve ser projetado, fabricado e testado de acordo com as normas internacionais, como segue:

|

Quality Control Standard |

|

|

ISO 9001 |

Quality Management Systems |

|

ISO 14001 |

Environmental Management Systems |

|

Component Material Standard |

|

|

IEC 60228 |

Conductors of insulated cables |

|

Cable Standard |

|

|

IEC 60840 |

Power cables with extruded insulation and their accessories for rated voltages above 30 kV (Um = 36 kV) up to 150 kV (Um = 170 kV) – Test methods and requirements |

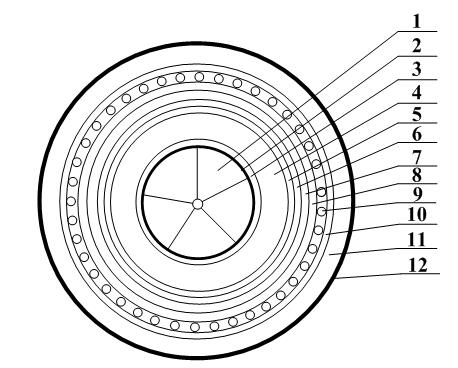

3. ESTRUTURA DOS CABOS para cabo de 66kV

CU / XLPE / LS / CWS / PEAD 38/66 (72,5) kV 1 × 1000 mm2

|

Structure |

Nominal thickness mm |

Nominal diameter mm |

|

1 Five(5) Milliken (segmental) copper conductor |

/ |

38.8±0.6 |

|

2 Semi-conductive tape |

0.14 |

39.4 |

|

3 Conductor screen(wrapping & extruding) |

2.0 |

42.8 |

|

4 XLPE insulation |

12.0 |

66.8±1.5 |

|

5 Insulation screen |

1.0 |

68.8 |

|

6 semi-conductive water blocking tape |

2.0 |

70.8 |

|

7 lead sheath |

3.0 |

76.8 |

|

8 Semi-conductive water blocking tape |

2.0 |

78.8 |

|

9 Copper wire screen with c opper tape wrapping(gap) |

Nominal sectional area 120.0mm2 |

81.8 |

|

10 non-conductive water blocking tape |

0.6 |

82.8 |

|

11 HDPE outer sheath |

4.5 |

91.8 |

|

12 semi-conductive layer(extruding) |

0.5 |

92.8±3.0 |

A bainha flexível com fio de cobre permite carregar correntes de curto-circuito juntas

4. Particularidades Técnicas Garantidas

|

No |

DESCRIPTION |

UNIT |

VALUEREQUIRED |

|

1 |

Manufacturer |

|

Beijing Huayuan Gaoke Cable.Co.,Ltd.

|

|

2 |

Cable size |

mm2 |

1000(nominal) |

|

3 |

Cable type |

|

CU/XLPE/LS/CWS/HDPE |

|

4 |

Voltage Grade(U0/U(Um) |

KV |

38/66(72.5) |

|

5 |

Reference Standard |

|

IEC 60840 |

|

6 |

No. and cross sectional area of conductor |

|

1C 1000sqmm |

|

7 |

Conductor material |

|

Copper |

|

8 |

Shape |

|

Five(5) Milliken (segmental) |

|

9 |

Nominal diameter of conductor |

mm |

38.8 |

|

10 |

Conductor Screen materials |

|

Simi-conduction tape + Extruded semi-conducting compound |

|

11 |

Nominal thickness of conductor screen |

mm |

2.0(wrapping + extruding) |

|

12 |

Insulation material |

|

super clean XLPE |

|

13 |

Nominal thickness of insulation |

mm |

12.0 |

|

14 |

Nominal diameter over insulation |

mm |

66.8 |

|

15 |

Insulation screen material |

|

Extruded semi-conducting compound |

|

16 |

Nominal thickness of insulation screen |

mm |

1.0 |

|

17 |

Metallic Screen material |

|

copper wire with copper tape binder tape (gap) |

|

18 |

Short circuit current rating(t=1.0sec) |

|

|

|

|

Of conductor |

kA |

144 |

|

|

Of metallic screen |

kA |

≥25(lead sheath with copper wire) |

|

19 |

Outer sheath material |

|

HDPE |

|

|

Colour |

|

yellow |

|

20 |

Nominal thickness of outer sheath |

mm |

4.5 |

|

21 |

Nominal thickness of extrude semi-conductive layer |

mm |

0.5 |

|

22 |

Nominal overall diameter of cable |

mm |

92.8 |

|

23 |

Approx. weight of cable |

kg/km |

21860 |

|

24 |

Minimum bending radius |

mm |

2320 |

|

25 |

Max.D.C. Conductor resistance at20`C |

Ω/km |

0.0176 |

|

26 |

Nominal capacitance per phase |

uF/km |

0.30 |

|

27 |

Max. current rating in air at 40° C |

A |

1442(1 circuit ,phase spacing 250, flat formation, a point earthed or cross connected) |

|

28 |

Max. current rating in ground at 25° C |

A |

1273circuit ,phase spacing 250, flat formation, a point earthed or cross connected ,depth of laying 1200 mm ,thermal resistivity of soil 1.0 k.m/W) |

|

29 |

Max. conductor temperature on continuous |

℃ |

90 |

|

30 |

Max. conductor temperature in short circuit |

℃ |

250(not exceed 5s) |

5. REQUISITOS DE ENSAIO PARA EHV Power Cables

O teste do cabo deve ser realizado de acordo com a norma aplicável de cabos de potência de 66 kV. Os seguintes itens de teste devem ser realizados de acordo com as normas IEC relevantes.

|

No. |

Test item |

|

Routine tests |

|

|

1 |

Partial discharge test |

|

2 |

Voltage test |

|

3 |

electrical test on oversheath of the cable |

|

Sample tests |

|

|

1 |

conductor examination |

|

2 |

measurement of electrical resistance of conductor and of metal screen/sheath |

|

3 |

measurement of thickness of insulation and oversheath |

|

4 |

measurement of thickness of metal sheath |

|

5 |

measurement of diameters |

|

6 |

hot set test for XLPE insulation |

|

7 |

measurement of capacitance |

Empresa

Oficina

Pacote

Entrega e Pagamento

Honra

Cliente

Beijing, Beijing, China

- Distribuidoratacadista

- Fabricante

- Serviço OEM

- Certificação da plataforma

- Vídeo

Envie sua pergunta a este fornecedor