1 / 2

Dois rolos A4 Cópia de Corte e embalagem da folha de papel

$175000.00

≥1 Set/Sets

Model:

- ZX-A4

| Model No. : | ZX-A4 |

|---|---|

| Brand Name : | Innono |

| Applicable industry : | Printing Shops,Energy &Amp; Mining,Construction Works,Machinery Repair Shops,Advertising Company,Retail,Manufacturing Plant,Food Shop,Building Material Shops,Garment Shops,Restaurant,Food &Amp; Beverage Factory,Home Use |

Chuzhou, Anhui, China

- Fabricante

- Serviço OEM

- fornecedor de ouro

- Certificação da plataforma

Descrição do produto

Linha de produção de papel de cópia A4

ESPECIFICAÇÃO

2.1. Echnics de _ E Quipment

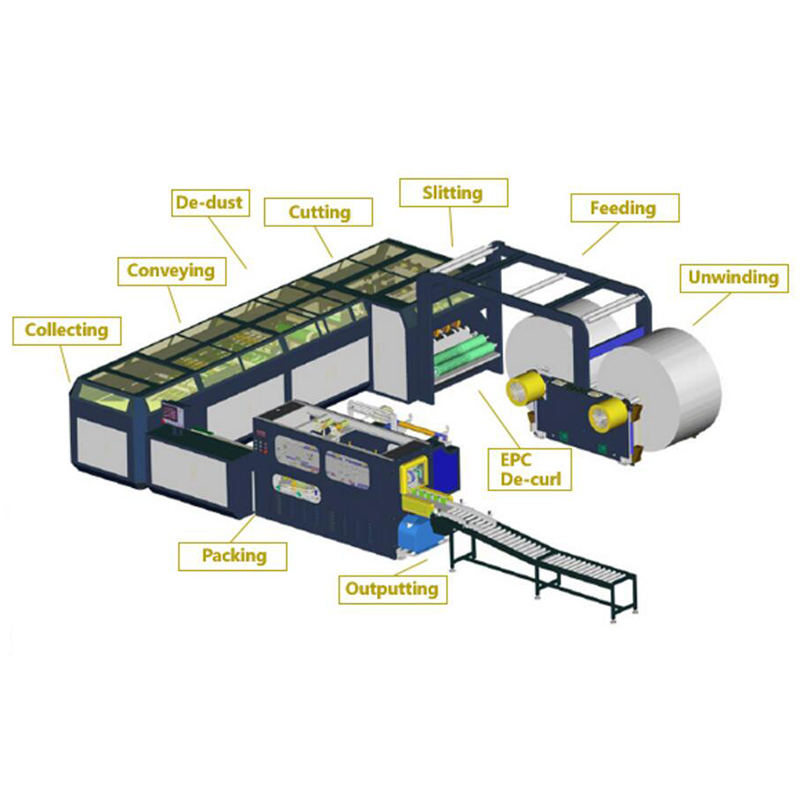

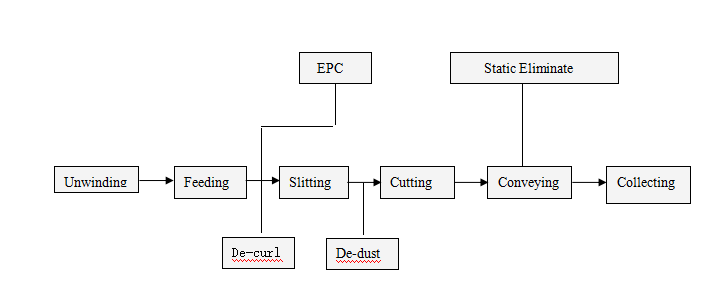

Como técnicas de nossa máquina, descrevemos as funções relacionadas e o fluxo de trabalho para produtos de papel: Despojamento → Corte → Transporte → Coleção → Embalagem.

![]()

A. A4- 2 (bolso) Máquina de folha de tamanho de corte

A.1 . Parâmetro técnico principal

|

Paper Width |

: |

Gross width 850mm, net width 840mm |

|

Cutting numbers |

: |

2 cutting-A4 210mm (width) |

|

Paper roll’s diameter |

: |

Max.Ф1450mm. Min.Ф600mm |

|

Paper core’s diameter |

: |

3”(76.2mm)or 6”(152.4mm) or according to the clients’ demand |

|

Packing Paper grade |

: |

High-grade copy paper; High-grade office paper; High grade Free Wood paper etc. |

|

Paper weight |

: |

60-100g/m2 |

|

Sheet length |

: |

297mm ( specially design for A4 paper, the cutting length is 297mm) |

|

Ream amount |

: |

500 sheets Max. Height: 45-55mm |

|

Production speed |

: |

Max 0-200m/min(depends on different paper quality) |

|

Max. Numbers of cutting |

: |

Max841/min |

|

Output of the ream |

: |

Max 13reams/min |

|

Load of cutting |

: |

100g/m2 (1×100g/m2) |

|

Cutting accuracy |

: |

±0.2mm |

|

Cutting condition |

: |

No variation of the speed, no break, cut all the paper at one time and need the eligible paper. |

|

Main power supply |

: |

3*380V /50HZ |

|

Voltage |

: |

220V AC /24V DC |

|

Power |

: |

23KW |

|

Air consumption |

: |

200NL/min |

|

Air pressure |

: |

6 bar |

|

Edge cutting |

: |

5~15mm×2 |

|

Safety standard |

: |

Design according the safety standard of China |

A.2. Configuração do padrão

1 . Descontraia Stand (1Sets = 1rolls)

Tipo A-1: CHM-A4- 2

|

1) Machine Type |

: |

Each machine table can take 2 sets of shaftless paper rack. |

|

2) Diameter of the paper roll |

: |

Max. Ф1450mm |

|

3) Width of the paper roll |

: |

Max. Ф850mm |

|

4) Paper rack’s material |

: |

Steel |

|

5) Clutch device |

: |

Pneumatic Braker and control |

|

6) Clip arm’s adjustment |

|

Manual adjust by oil pressure |

|

7) Paper core demanding |

|

3”(76.2mm) air expansion shaft chuck |

2. Sistema automático de controle de tensão

Tipo A-2: sistema automático de controle de tensão

|

1) When the paper through inductor, that automatic feedback to the PLC control system to increase brake load, increase or reduce the tension that control the paper tension automatically. |

3 sistema de faca de corte de alta precisão

A-3 tipo: sistema de faca de corte de alta precisão

|

4) Paper feeding wheel |

|

|

|

Upper wheel |

: |

Ф200*550mm (rubber covered) |

|

Lower wheel |

: |

Ф400*550mm (anti-glide) |

|

5) Cutting knife group |

|

|

|

Upper cutting knife |

: |

1 sets 550mm |

|

Lower cutting knife |

: |

1 sets 550mm |

|

6) Driving group(High precision bear and belt drive) |

||

|

7) Main driving motor group: 15KW |

||

4. Sistema de transporte

A-4.Type: Sistema de transporte

|

1) Transporting by level and overlapping device |

|

2) High speed transporting belt and press wheel. Upper and lower transport belt corresponding pressure paper, automatic tension and close system. |

|

3) Static removal device(Include static removal bar and Negative ion generator) |

5. Sistema de coleta de papel

A-5 tipo: Sistema de coleta de papel

1) dispositivo automático para empilhamento de papel para cima e para baixo

2) Dispositivo de jogging e papel aplaudido arrumado. Controle por IVA de ar, quando o design

Folha, o cilindro para cima e para baixo pela barra de papel cortada. Depois do papel de transporte

Para o cinto, transporta para o cruzamento da mesa.

6. Acessórios

A-6 Tipo: Acessórios

|

Upper knife |

: |

1 sets 550mm Material: compounding of tungsten steel |

|

Lower knife |

: |

1 sets 550mm Material: compounding of tungsten steel |

|

Upper slitting knife |

: |

5 sets Ф180mm Material: SKH |

|

Lower slitting knife |

: |

5 sets Ф200mm Material: SKH |

B. CHM-A4B Máquina de embrulhar

B.1. Principais parâmetros técnicos:

|

Paper Width |

: |

Gross width:310mm ;net width :297mm |

|

Ream packing high |

: |

Max 55mm ; Min 45mm |

|

Packing roll dia |

: |

Max.1000 mm ; Min.200mm |

|

Packing roll width |

: |

560mm |

|

Packing sheets weight |

: |

70-100g/m2 |

|

Packing sheets grade |

: |

high-grade copy paper, high-grade office paper, high-grade offset paper etc. |

|

Design speed |

: |

Max 50 reams/min |

|

Operation Speed |

: |

Max 35 reams/min |

|

Packing condition |

: |

no speed variations, no breaks, cut all the paper at one time and qualified packing paper. |

|

Driving |

: |

AC Servo Precision Control |

|

Main power supply |

: |

3*380V /50HZ( or as required) |

|

Voltage |

: |

220V AC /24V DC (or as required) |

|

Power |

: |

18KW |

|

Compressing air consumption |

: |

300NL/min |

|

Air pressure |

: |

6bar |

B.2. Configuração:

|

1. Conveyer system for reams placement ( 800*1100) |

: |

One set |

|

2. Ream accelerated to placing system |

: |

One set |

|

3. Unwind stand for packing roll |

: |

One set |

|

4. Lifting system for reams |

: |

One set |

|

5. Pressing and tighten system for reams |

: |

One set |

|

6. Lower folding system for packing sheets |

: |

Two sets |

|

7. Angle overlapping system for packing sheets |

: |

One set |

|

8. Steadfastness angle overlapping for packing sheets |

: |

One set |

|

9. Spraying hot melt glue system for packing sheets |

: |

One set |

|

10. PLC system for alarming, auto stop of break-down |

: |

One set |

|

11. PLC controlling system |

: |

One set |

C. Toda a máquina é controlada pelo PLC.

Incluído a seguinte função: controle de velocidade, contagem de papel, saída de resma de papel, alarme de falha e parada automática (indique o código de falha mostrado na tela do painel)

D. Prepare itens pelo comprador

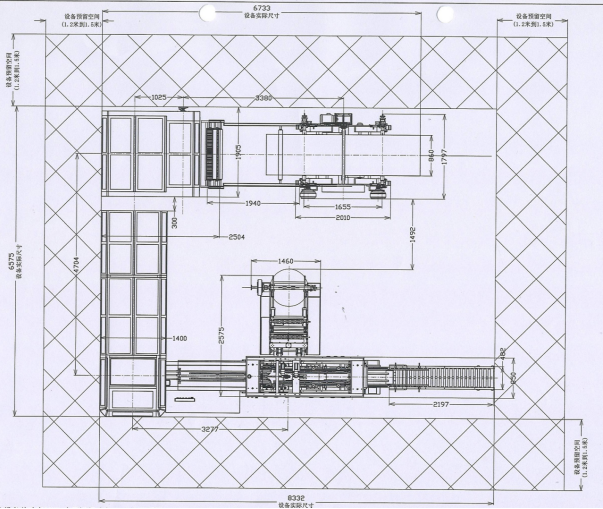

1 ) A engenharia civil e subestrutura desta máquina

2 ) A fiação principal da máquina e a configuração da linha elétrica funcionam nesta caixa de controle da máquina.

3 ) Fonte de pressão do ar e tubo para esta máquina.

4 ) O trabalho de suspensão e descarga em cena.

E. Outros termos

Este design de máquina pelo mais novo desenvolvimento técnico e tecnológico; portanto, no governante de não afetar a produção e a qualidade, continuamos sendo o direito de modificar e mudar.

Anhui Innovo Bochen Machinery Manufacturing Co., Ltd. is a global business enterprise engaged in the manufacture, marketing, research and development of machinery. Our firm also provides import and export operations and technical training. We ar

Chuzhou, Anhui, China

- Fabricante

- Serviço OEM

- fornecedor de ouro

- Certificação da plataforma

Envie sua pergunta a este fornecedor