Video

1 / 4

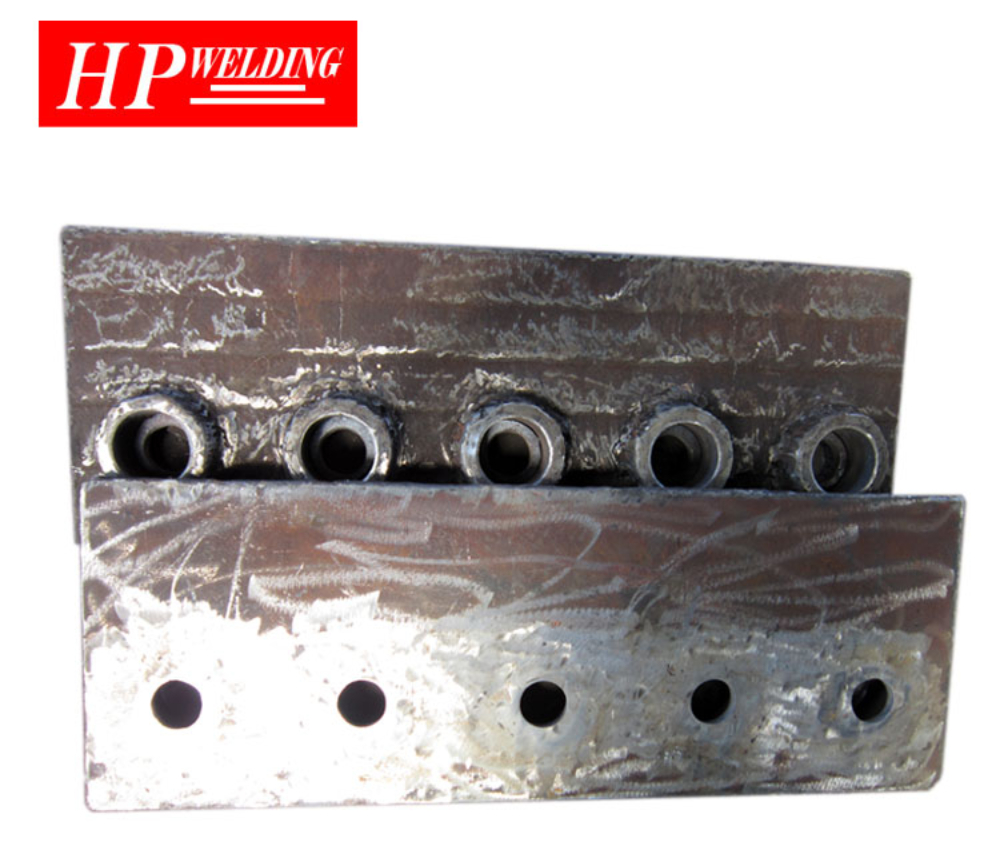

Tampa do moinho de peças de desgaste

Options:

- Comply to the drawings required

| Model No. : | HP-FP |

|---|---|

| Brand Name : | Placa HP, Soldagem HP |

| place of origin : | China |

Suzhou, Jiangsu, China

- Agente

- Distribuidoratacadista

- Fabricante

- Empresa de comércio

- Serviço OEM

- fornecedor de ouro

- Certificação da plataforma

- Certificação SGS

- Expo online

Descrição do produto

Hardfacing Chute Liners are made by bimetal welding wear resistant alloy steel plate, its substrate using common Q235 steel plate, and Chutes Hopper Liners are composed of advanced alloy welding which was joint research and development by our company and scientific research institutions. The unique process ensures that all lining components work well to protect your equipment. We supply Discharge Funnel Parts, Mill Abrasion Linings, Chute Liner, Ore Chute Liner, Cyclone Wear Parts, Discharge Funnel Parts, etc...

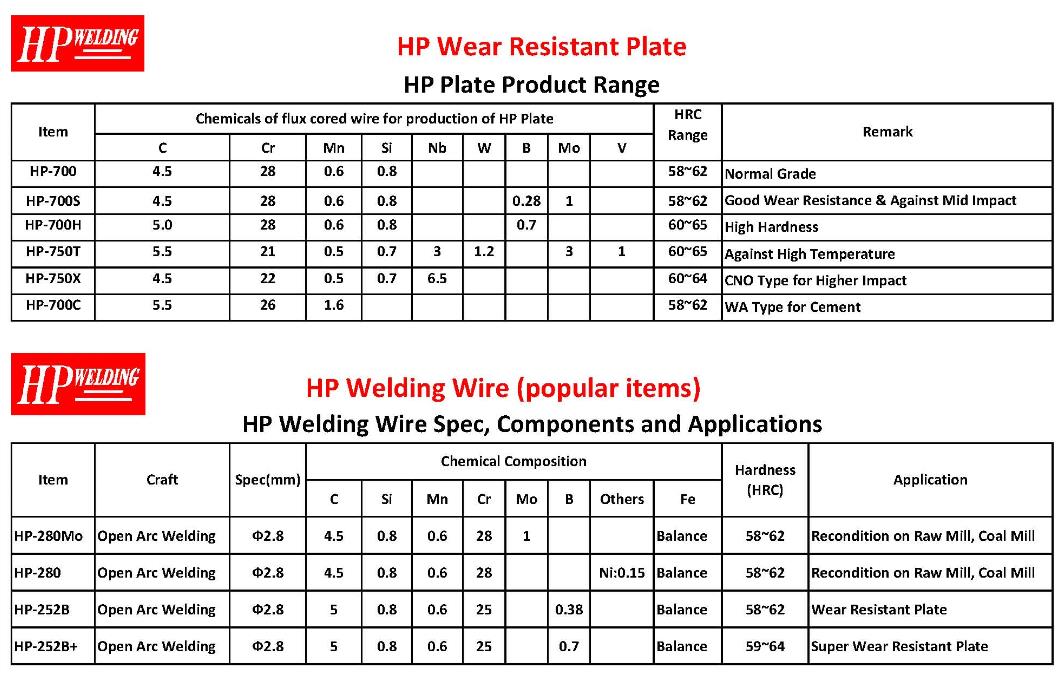

Standard Specifications of HP Wear Plate :

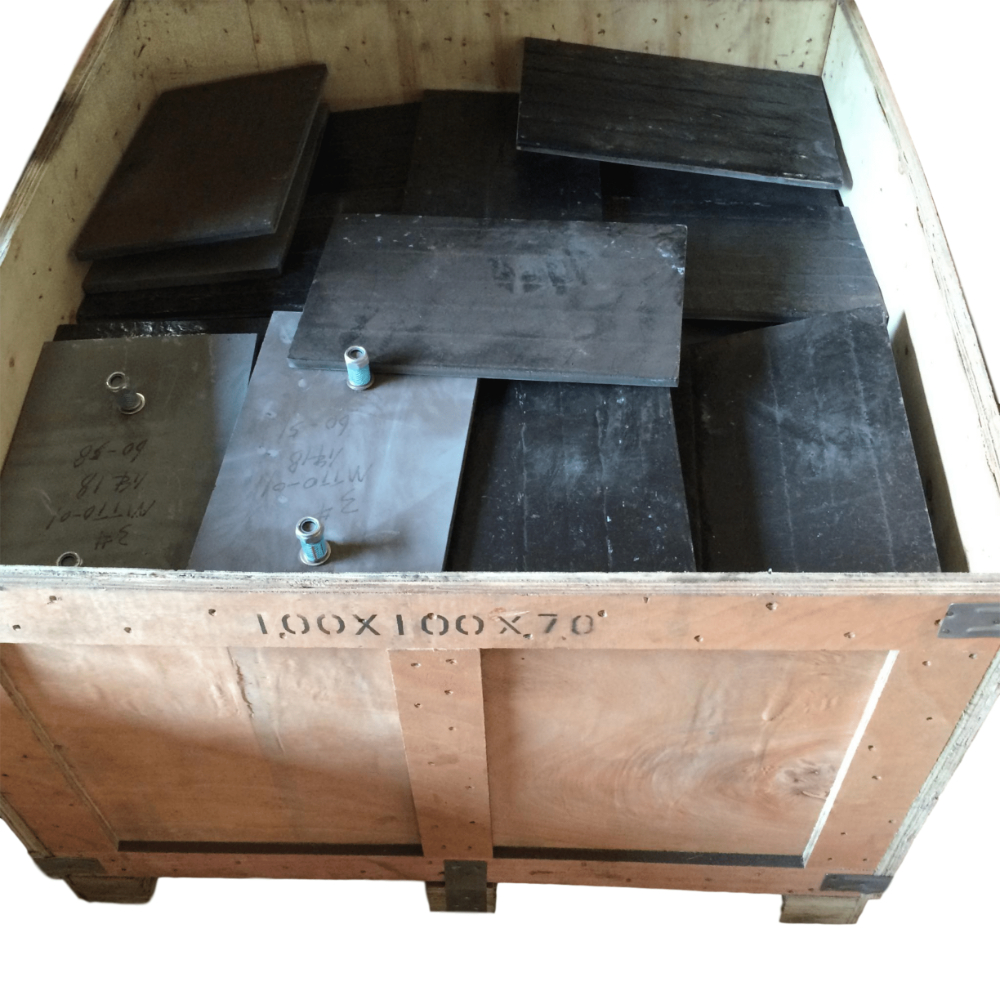

Packing & Delivery of Wear Plate

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 30 days after order confirmation

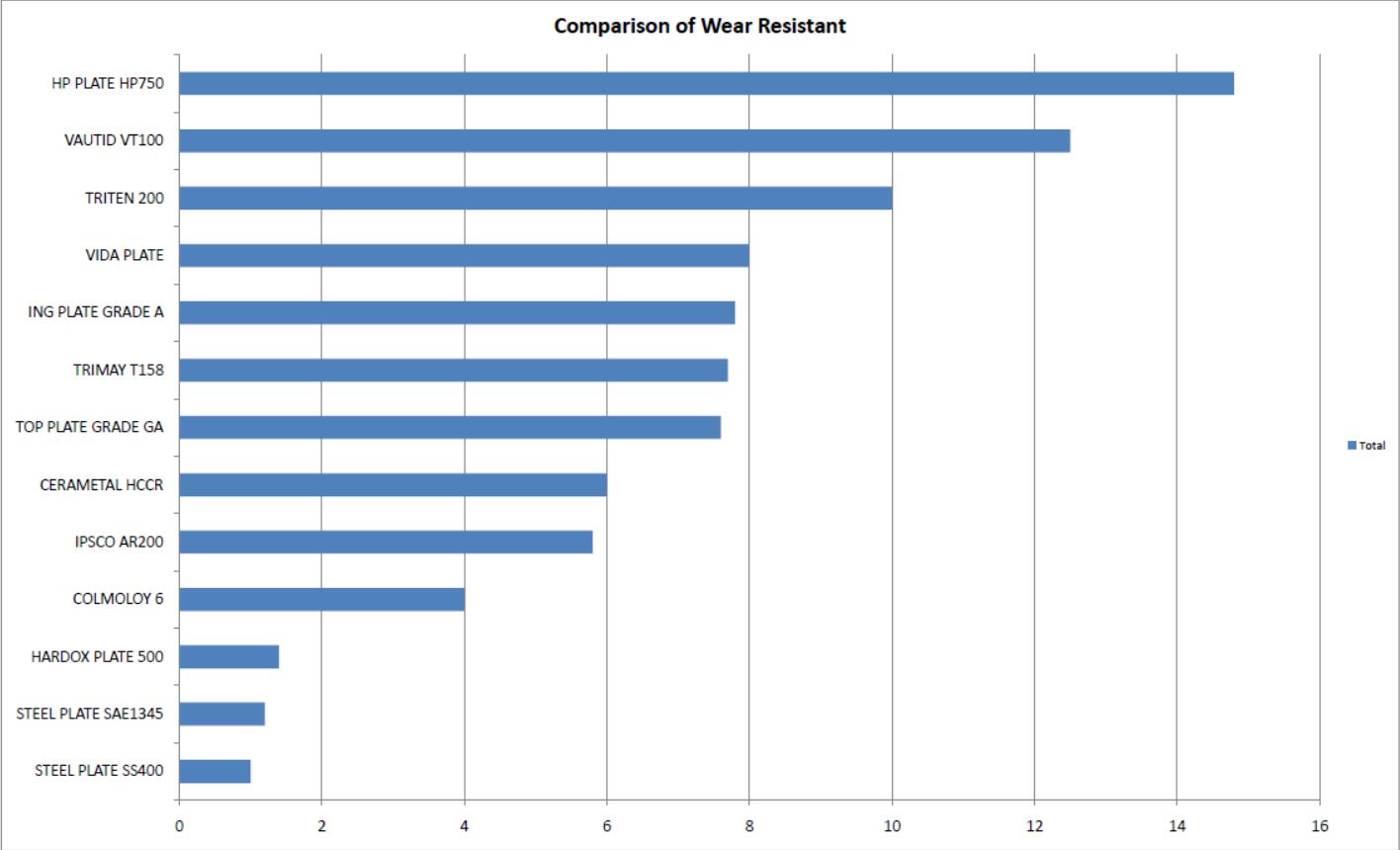

Anti-abrasion Comparison_HP Plate vs Other Plate

Informações da Empresa

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert providing one-stop wear solution & products.

HP Wear Products Range:

HP Factory Laboratory

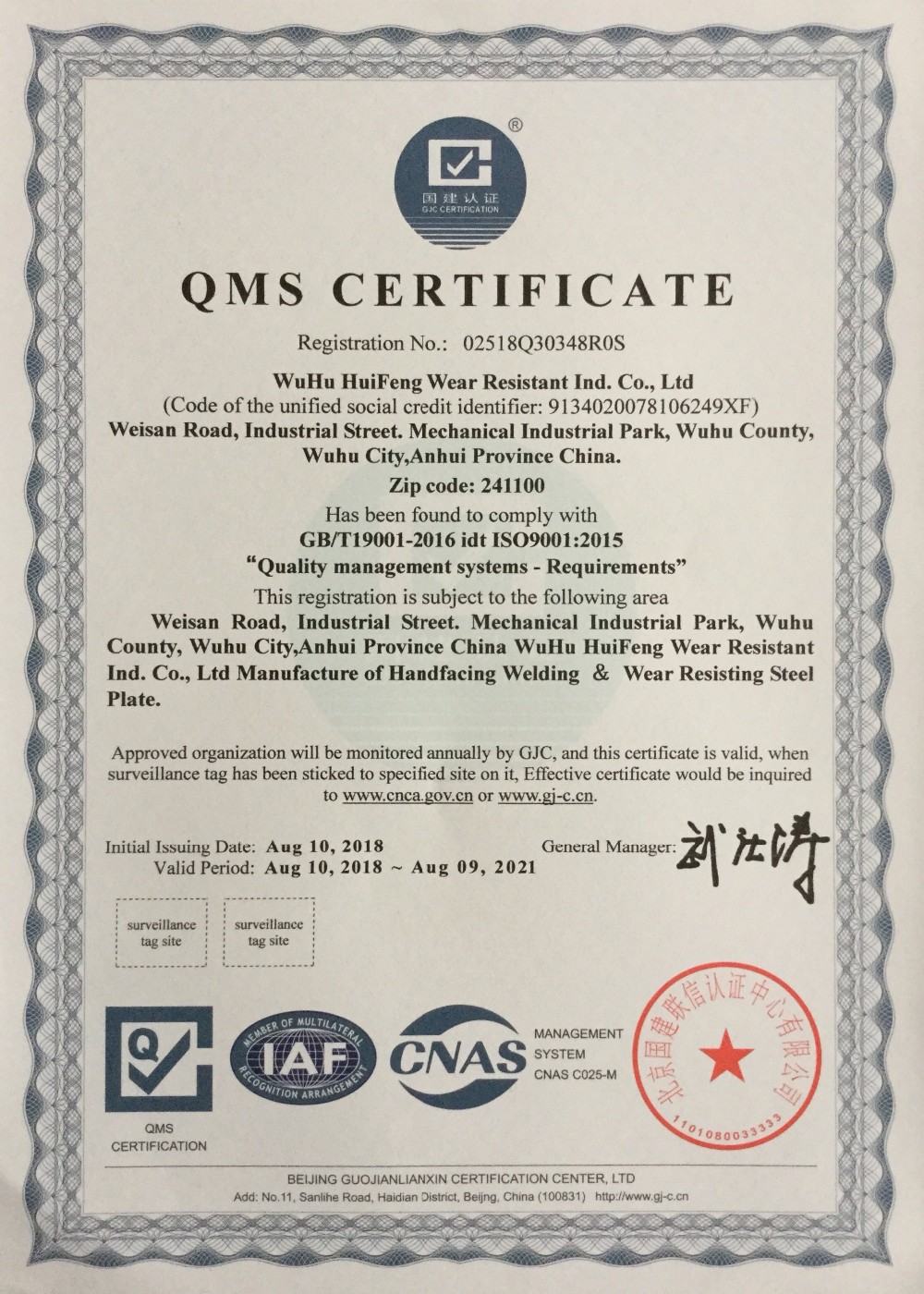

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Responda: T he typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Video

Suzhou, Jiangsu, China

- Agente

- Distribuidoratacadista

- Fabricante

- Empresa de comércio

- Serviço OEM

- fornecedor de ouro

- Certificação da plataforma

- Certificação SGS

- Expo online

Envie sua pergunta a este fornecedor