1 / 5

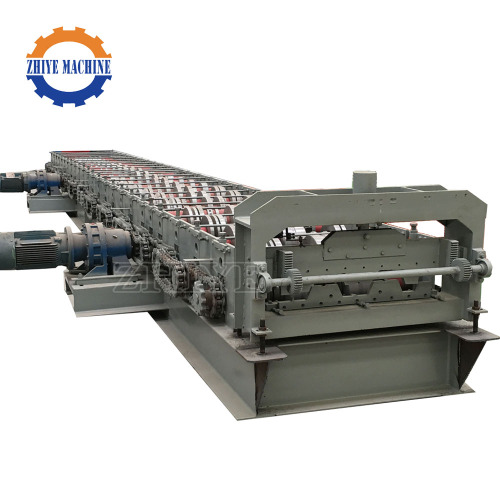

Deck Floor Cold Roll Forming Machine

| Model No. : | customized |

|---|---|

| Brand Name : | ZY |

| Certification : | CE |

Cangzhou, Hebei, China

- Agente

- Distribuidoratacadista

- Fabricante

- Organização

- Serviço

- Empresa de comércio

- Serviço OEM

- Certificação da plataforma

- Vídeo

Descrição do produto

Deck Floor Cold Roll Forming Machine

products details:

Panels produced by this machine are mainly used as the floor decking in Russia. It has features of high wave, high strength, high degree automatically producing, lower cost and so on.

This panel is set up with concrete, which has good adhesiveness. This not only can save steel moulding plate, but also can decrease the load capacity of floor decking. Therefore, steel quantity of the whole project is decreased and can save money surely.

Technical pararmeter of product line:

1.Suitable process material: colored steel sheet, aluminium steel sheet, and galvanized steel

2.Applied slab thickness:0.3-1.0mm

3 Charge in width:1000mm

4. Line speed:16m--18m/min

5. Rolling rows:16rows

6. Rolling diameter:70mm

7. Dimensions15M*1.9m*1.4m

8. Weight:5t

9. Power:11kw+4kw

Processing technique and deployment:

Uncoiler

Feeding platform

molding core

Molding shearing mechanism

Hydraulic station

Computer control cabinet

Counter

Optional equipment:

Manual uncoiler frame in different tons

Hydraulic automatic uncoiler

Working flow:

Decoiling the sheet--sheet guiding---roll forming---measure length---cutting the panel---panels to the supporter

Packaging and shipping:

1.One 40ft container for loading one set machine with manual decoiler;

2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film;3.Spare parts and some small parts packed in plastic tooling box;

Our Service:

Technical Support

Fully providing technology supports both within and after the warranty period. Feed back to our customers at the first time.

Spare Parts

Promptly providing spare parts and wearing parts.

Upgrade

Improve technology and upgrade of equipments.

Other service

Raw Materials

Supply of raw materials made in China with good quality, quick delivery and reasonable price

Company information:

Cangzhou Zhiye Cold Forming Machinery Co.,Ltd has been entitled with the [key private enterprise" by the local government and over the years, we have been dedicated to the research&development as well as the fabrication of the forming machines of metallic plate cold bending roller. Owing to the unique the managerial fashion and the ability on product-developing, we have placed ourselves in a leading position amid the competitors in the same field and our products have won the favor from the steel construction industry for its light and ingenious structure and the appropriate design as well.

Contact:

Cangzhou, Hebei, China

- Agente

- Distribuidoratacadista

- Fabricante

- Organização

- Serviço

- Empresa de comércio

- Serviço OEM

- Certificação da plataforma

- Vídeo

Envie sua pergunta a este fornecedor